Solutions

Our services at a glance

Personalization

We provide our customers with machines that they can configure according to their specific needs by choosing the components they want to use for their machining operations.

Automation

As a manufacturer of high-precision lathes, we are the ideal partner to work with you on the complete automation of your machine. The robot's integration is already defined at the product design stage, enabling us to optimize the overall footprint, among other things.

The robot can be controlled directly from the machine's NC screen, using a dedicated HMI that enables the following actions:

- Program selection

- Start and pause robot program

- Reset alarms

- Palletizing and loading speeds into the machine

- Position of first part on pallet

- Safe position of machine axes to avoid collisions

- Robot position can be relearned and saved

With the latest Fanuc controller, we have developed a function that allows the robot to be moved in a Cartesian coordinate system, using the machine's handwheel. This makes it very easy to adjust the robot to a precise position.

With these features, we offer users a level of comfort and security that few other integrators can guarantee. Our interface will help you with your set-up and handling tasks.

Applications

Our applications engineers analyze the feasibility of your parts and calculate machining times to propose the machine best suited to your needs.

We also carry out machining trials at our customers' request. Depending on the type of test to be carried out, these will be subject to a charge, depending on the duration of the test, the tooling we have to purchase, etc. We'll be happy to make you an offer.

Does your industrial project involve particularly complex machining ?

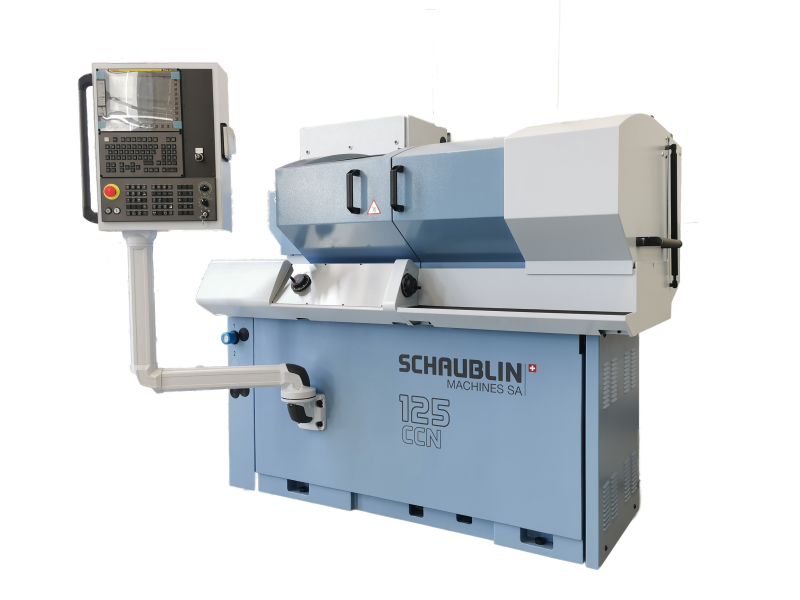

Demonstration

The machines in our sales program can be viewed in our showroom, where you can make an appointment to see the machines in action and get a precise idea of your future purchase.

Retrofit

Schaublin Machines SA offers a wide range of services to complement your experience of working with us. Overhauling individual machine components such as carriages, headstocks, etc., but also complete machines with new paint, replacement of mechanical parts, leveling, etc., is our advantage in serving you.

We also offer retrofitting, i.e. complete overhaul with replacement of the numerical control and adaptation to CE standards, of our older products.

Our company, and our overhaul department in particular, have many years' experience and extensive know-how. Machine overhauls are always carried out with precision, paying particular attention to the original construction. This is made possible by the preservation of documents dating back to the company's foundation, as well as all original drawings.