News

A PROJECT AIMED AT APPRENTICES

Collaboration between Schaublin Machines and Bobst for Apprentice Training

17 may 2023

In view of the reform of the polymechanics profession planned for 2026 and the new training plan for the polymechanics CFC initiated by the Confederation, the Bobst Vocational Training Department wanted to anticipate future changes as far as possible. By analysing the industrial world, a team of trainers noted that the role of robotic arms within companies is becoming increasingly important, particularly for machine tools. The aim is to optimise production times and improve the profitability of work in hidden time.

This is how the collaboration between Schaublin Machines SA and the Bobst Vocational Training Department in Mex came about.

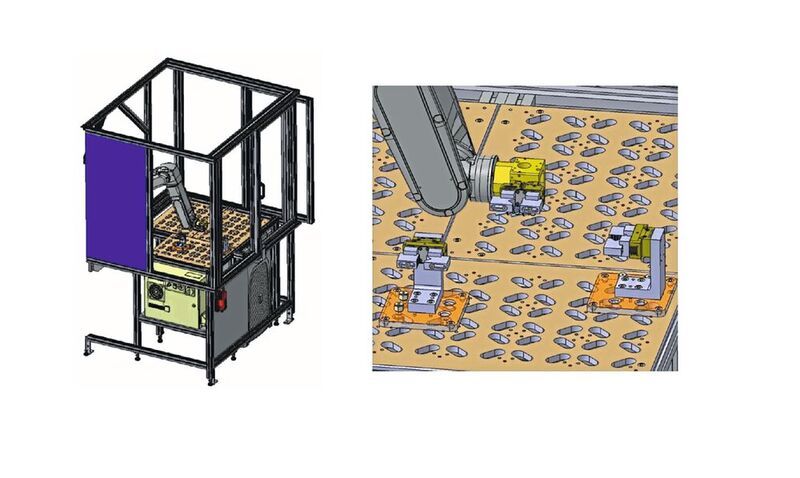

The system comprises a modular palletising system and a standard robot equipped with a modular multiple gripper (fig. 1 in the gallery on the right). This flexibility will make it possible to test a wide range of applications for polymechanics apprentices. The aim is to create a package with which the trainee can carry out mechanical assembly and programming in order to be as efficient as possible in relation to a given part. Thanks to this new tool, the Bobst training centre in Mex is proactive and in line with the new training reform.

This pack will be available on Schaublin Machines SA lathes and will benefit all schools and training centres. Tomorrow's polymechanics will be experts in the integration of Schaublin Machines SA automation applications. This automated cell is equipped with modular elements used to carry out multiple palletising exercises with accessories such as a washing and drying station, a turning station, etc. This will enable apprentices to learn how to position the robot in different configurations and manage all kinds of trajectories. In fact, one of the students at the training centre developed the 1st exercise as part of his end-of-apprenticeship work (TPI).

The students will be able to handle and machine different parts, while at the same time having the opportunity to deal with the constraints associated with automation. They will have to make the best choices regarding the type of pallets, the robot gripping system and the layout of the parts to be reached. Through these exercises, they will be adequately prepared for the hazards of machine tool industrialisation.

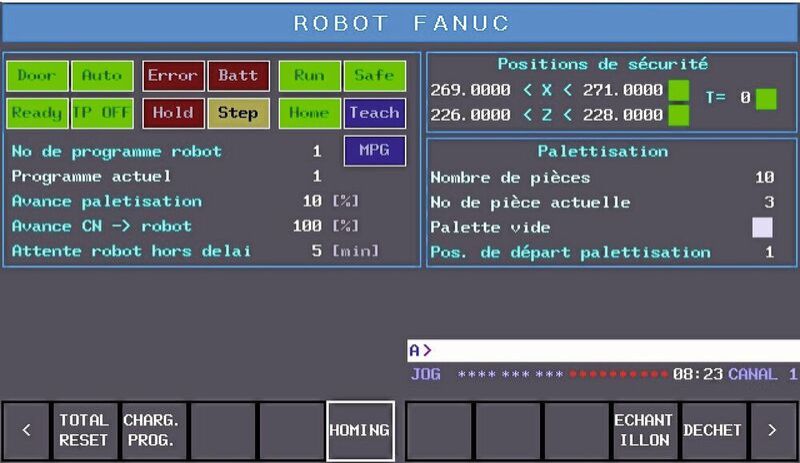

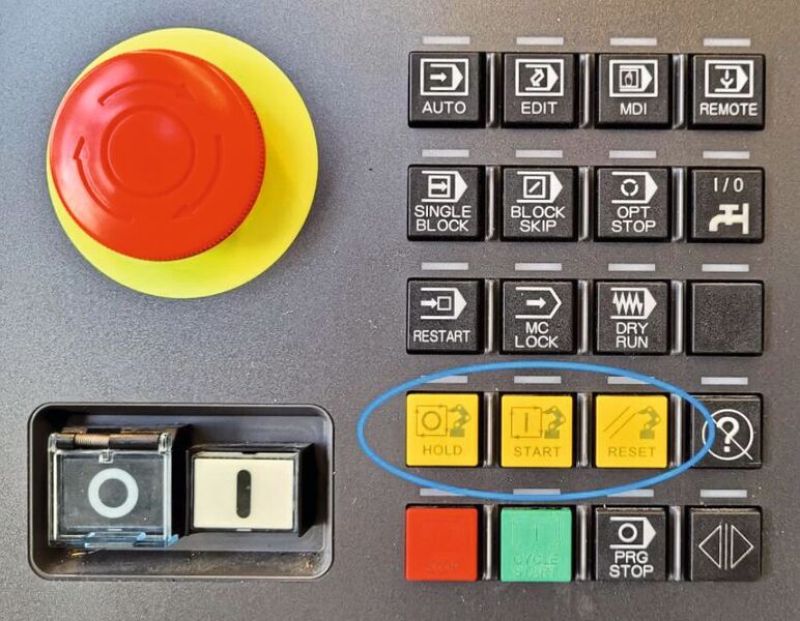

The visual aspect of the display is of great importance. That's why Schaublin Machines SA has put all its expertise into offering the user a simplified interface with pages dedicated to automation (fig. 2) and buttons in different colours (fig. 3). The robot can thus be controlled directly from the machine's NC screen. This interface is intuitive and gives a clear view of the overall status of the robot cell.

To make it easier for the students to follow the course, a screen will be placed on the side of the robot cage displaying the NC screen as well as the robot controller screen. In this way, the students will be able to follow the trainer's explanations live.